Is DTF printing durable?

Share

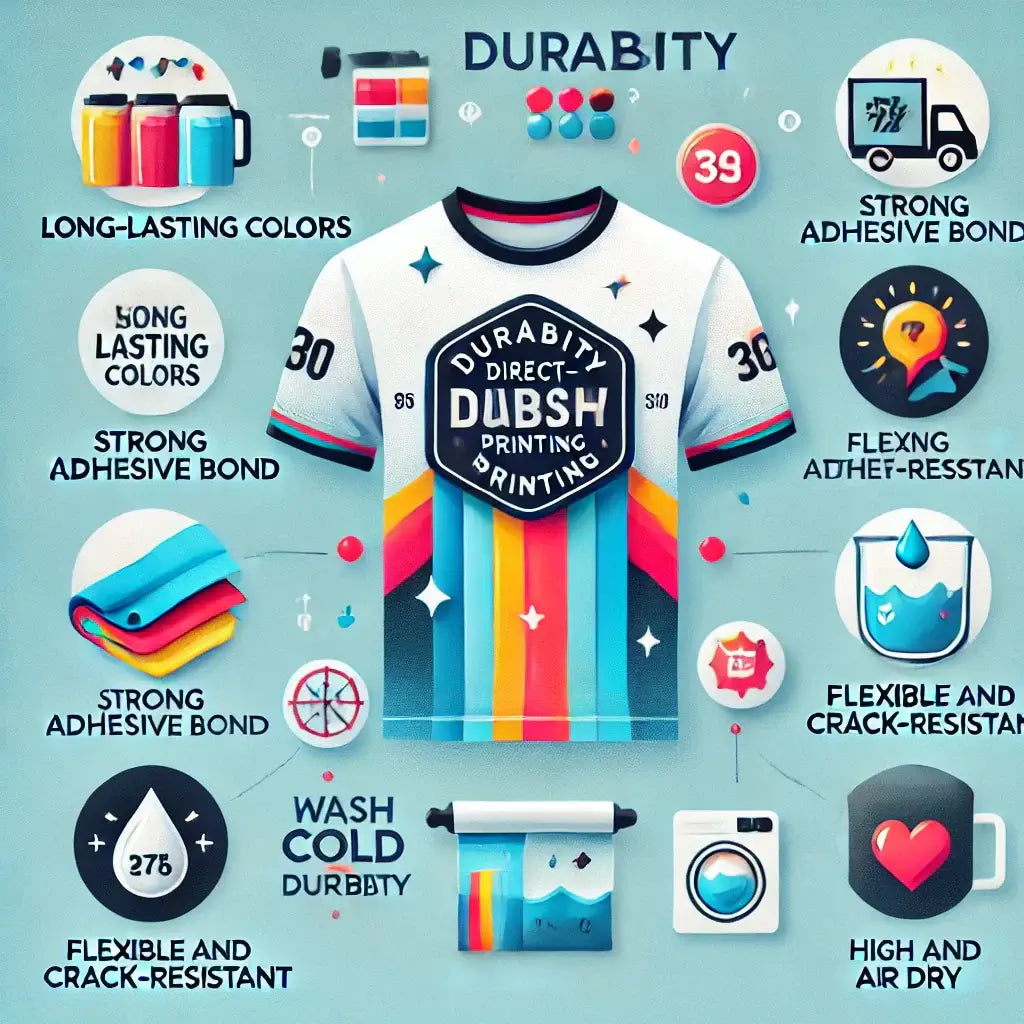

DTF (Direct-to-Film) printing is known for its durability. When applied correctly, DTF prints can last through numerous washes and maintain their vibrant colors and adhesion over time. Here are some reasons why DTF printing is durable:

1. Strong Adhesive Bond

- DTF printing uses a powdered adhesive that is heat-activated during the transfer process, creating a strong bond with the fabric. This adhesive layer is key to the print's longevity and helps it withstand wear and tear.

2. High-Quality Inks

- DTF inks are typically pigment-based, providing high color vibrancy and resilience. These inks are designed to hold up against fading, even after repeated washes.

3. Compatibility with Multiple Fabrics

- DTF prints adhere well to a wide variety of fabrics, including cotton, polyester, and blends. This versatility makes them a great option for maintaining print quality across different types of garments.

4. Flexibility and Resistance to Cracking

- DTF prints remain flexible and stretch with the fabric, which reduces the chance of cracking or peeling, even on garments that experience a lot of movement.

5. Long-Lasting Colors

- DTF prints retain their vibrancy over time. With proper care (gentle washing, avoiding high heat), colors can stay bright and vivid even after 40-50 washes or more.

Tips for Maximizing Durability

- Use Cold or Warm Wash Cycles: Hot water can degrade the adhesive bond.

- Avoid High Heat Drying: Air drying or using a low-heat setting extends the life of the print.

- Wash Inside Out: Reduces friction and wear on the printed area.

In short, DTF printing is highly durable, making it a reliable choice for custom apparel and items intended for long-term use.